Date: Jun 2025

Role: UX Designer/ Researcher

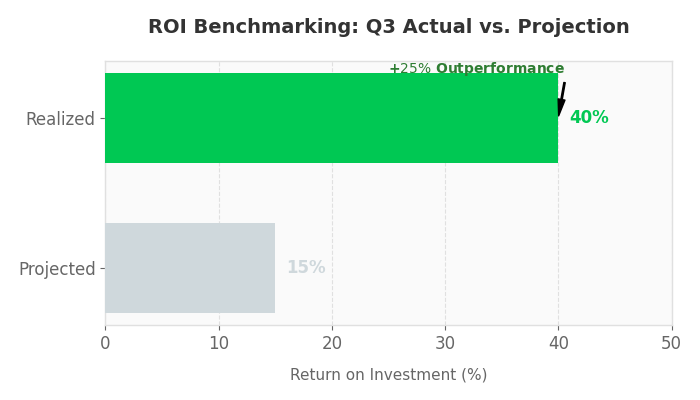

Impact Snapshot

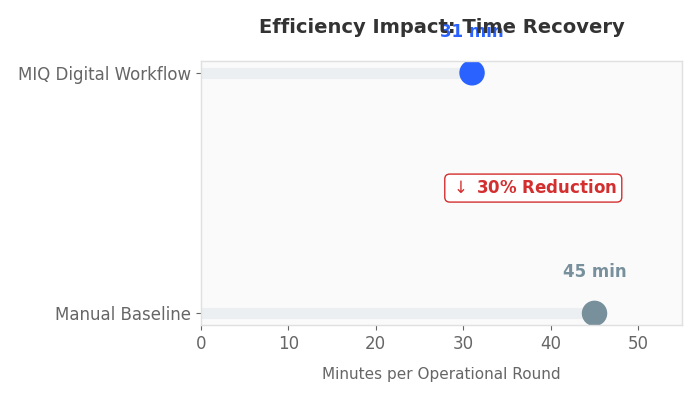

30%

Decrease in task completion time

Tools: Figma, Miro, Google Forms, Zoom

25%

Boost in data interpretation and accuracy

Duration: 6 Months

40%

Increasing in Pulp manufacturing ROI

The Problem

Factory workers previously managed refills, inspections, and maintenance via paper logs, requiring trips to a central control panel for data entry. This led to delays, errors, and suboptimal productivity, limiting focus on critical issues.

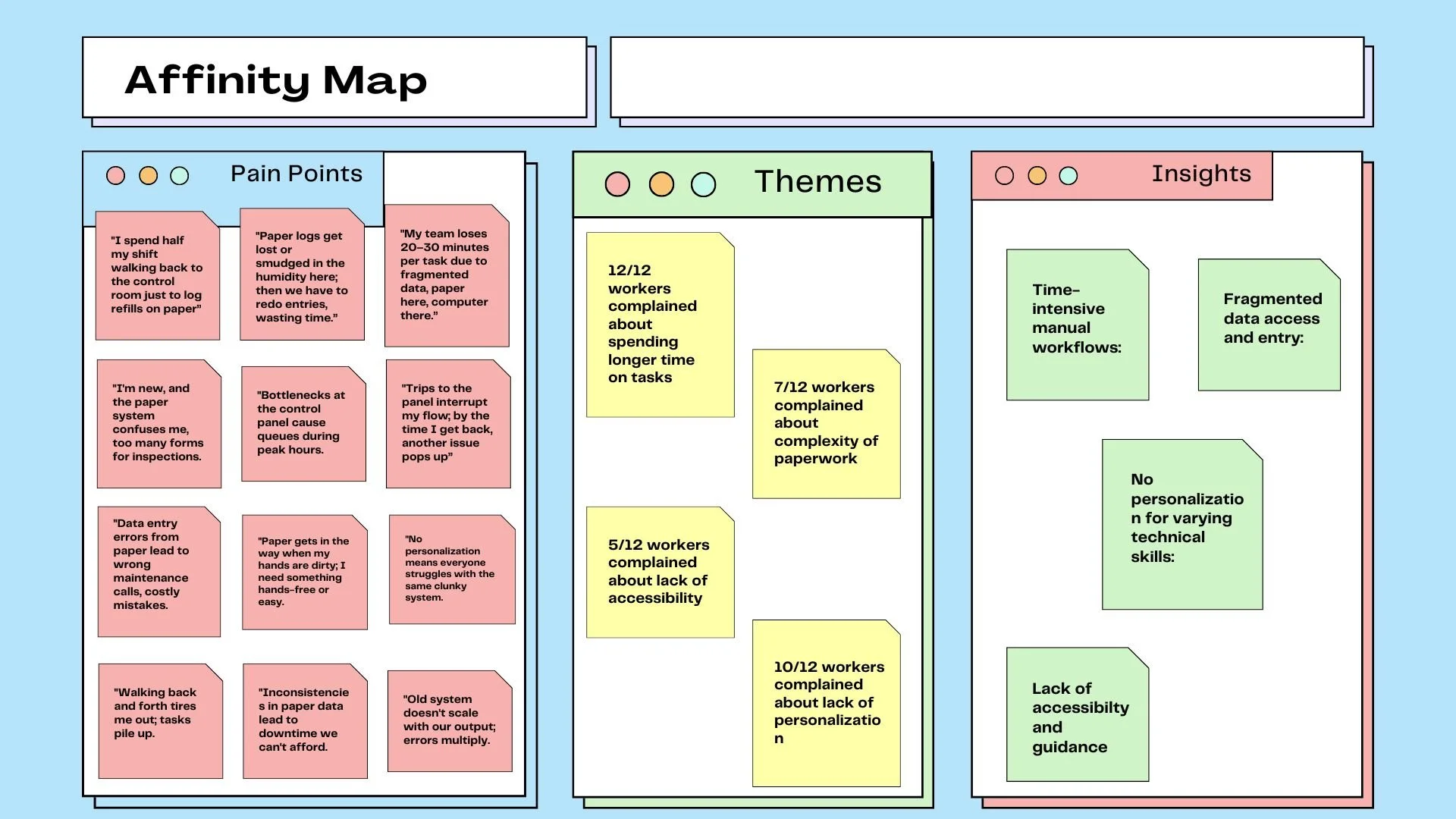

Time-intensive manual workflows: Factory workers used paper for tasks like refills and inspections. They had to walk to a central panel for data entry. This slowed operations. It reduced efficiency.

Fragmented data access and entry: Workers handled info across paper logs and digital inputs. The system was disjointed. It caused delays and inconsistencies. Errors rose in tracking mill activities.

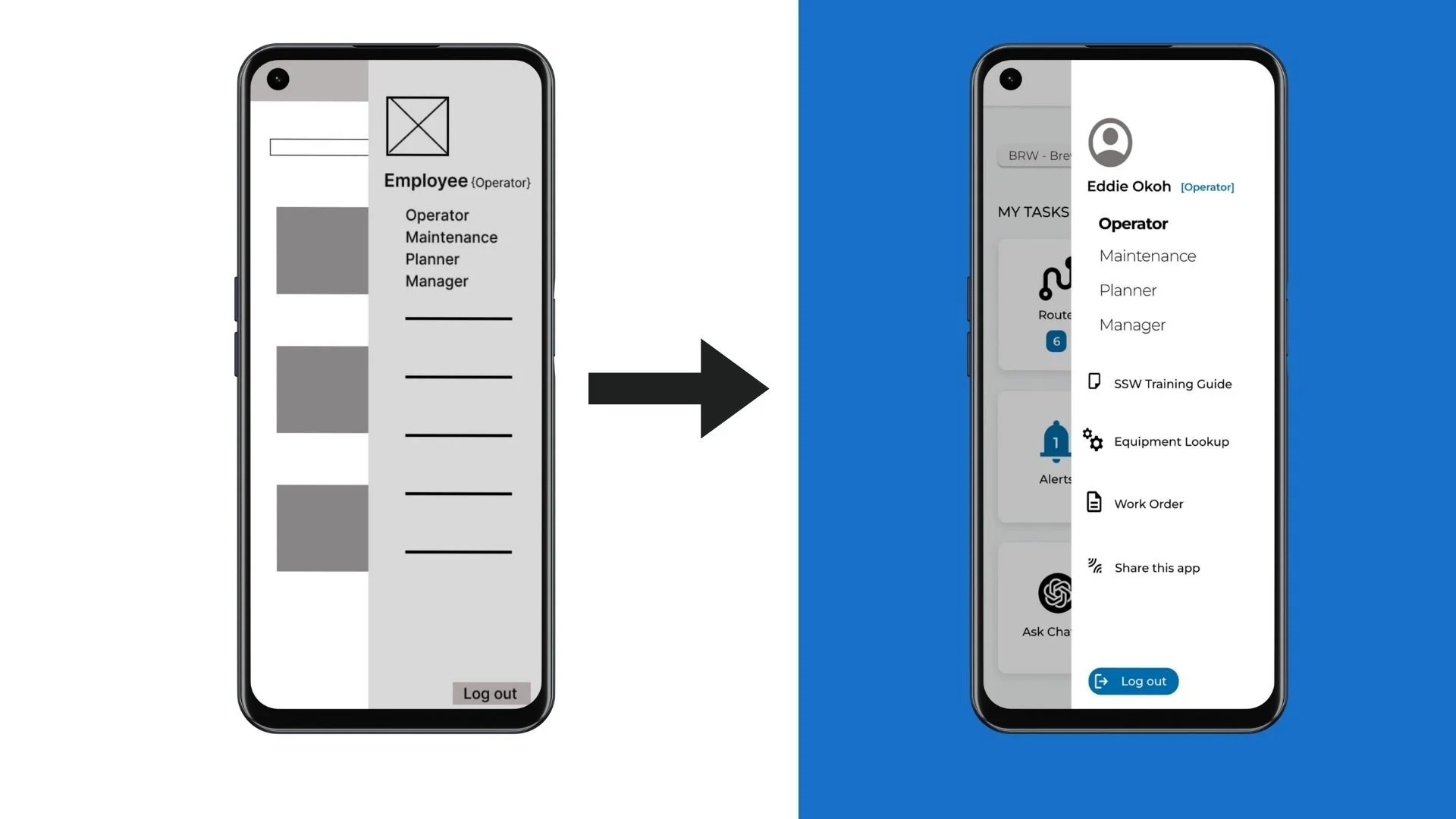

No personalization for varying technical skills: The approach was one-size-fits-all. It ignored tech proficiency differences. Interfaces were too simple or complex. This slowed adoption and performance.

The goal : Deliver an intuitive and accessible mobile dashboard that enhances efficiency and ROI.

Research & Discovery

My visit to Brewton

I conducted an on-site visit to the Brewton facility, engaging directly with a diverse group of factory workers through interviews and observations

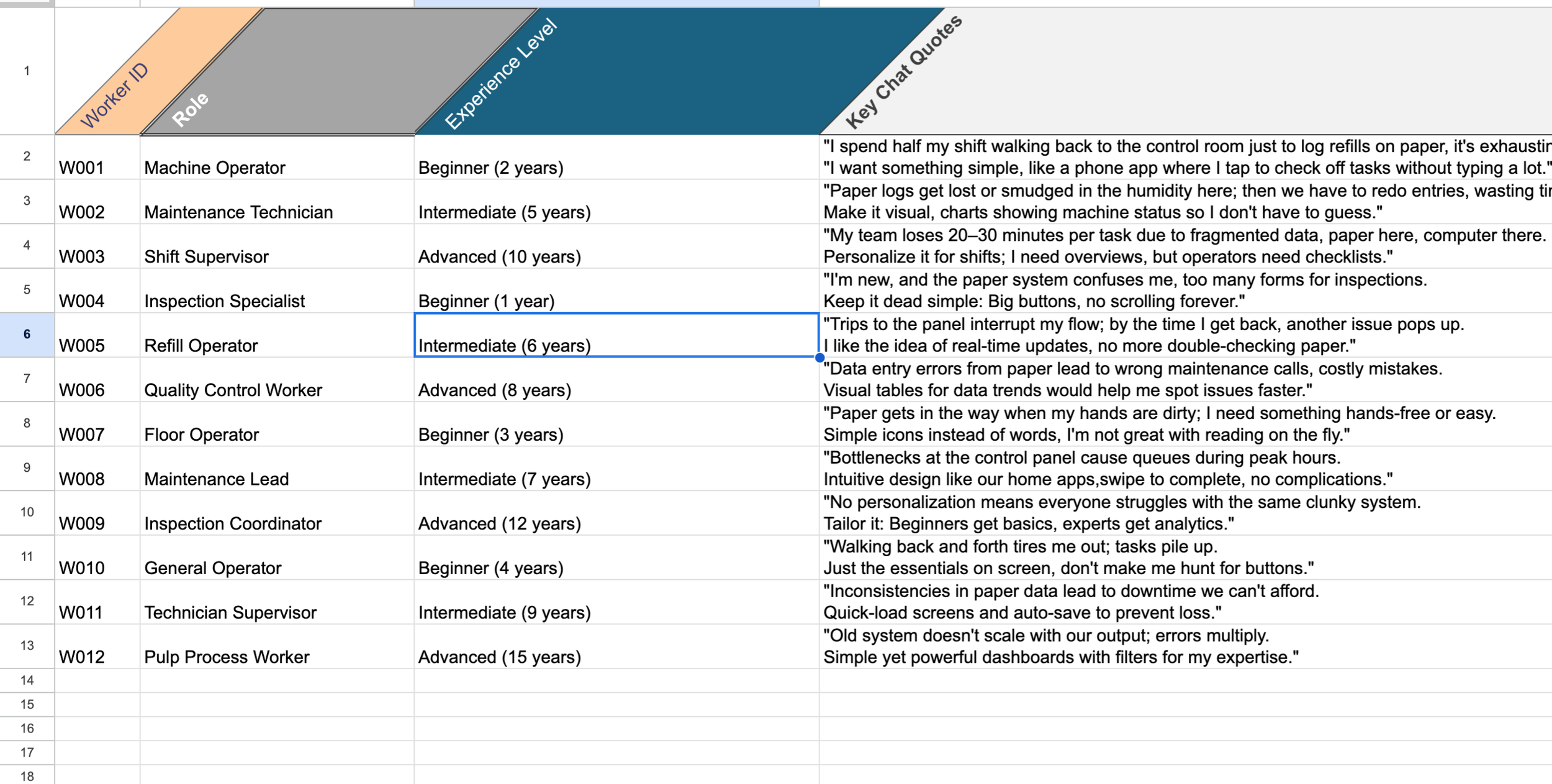

Interview Data

This hands-on approach revealed common frustrations, such as the time lost in manual documentation and the cognitive load of juggling paper records with operational duties.

Theme Analysis Summary

Analyzed data to identify common themes, crafting a clear problem statement shared with stakeholders for alignment.

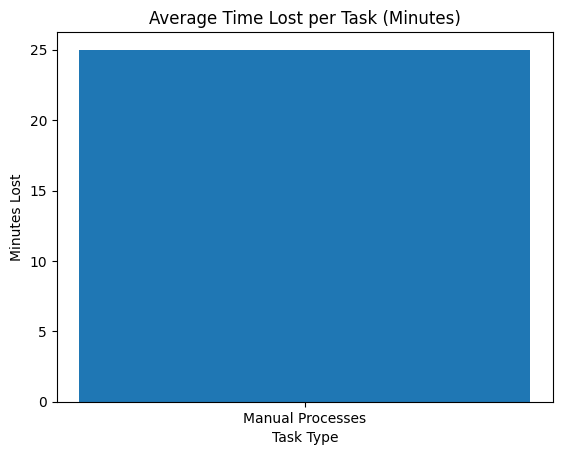

Bottlenecks: 100% of workers mentioned time loss from manual processes (avg. 20-30 mins/task). Physical trips and error-prone entry dominant.

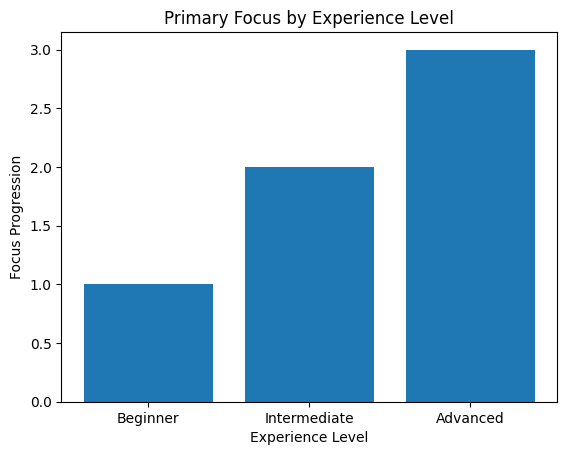

Diversity Insights: Beginners (n=4) focused on ease; Intermediates (n=4) on efficiency; Advanced (n=4) on customization.

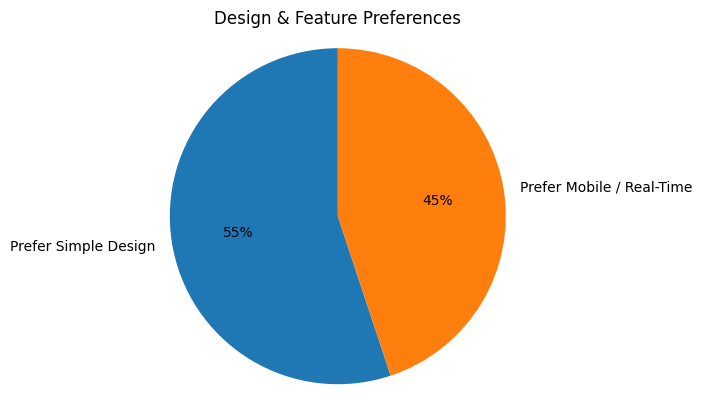

Simplicity Preferences: 55% favored intuitive, minimal designs (e.g., big buttons, visuals, personalization). 45% requested mobile/real-time features.

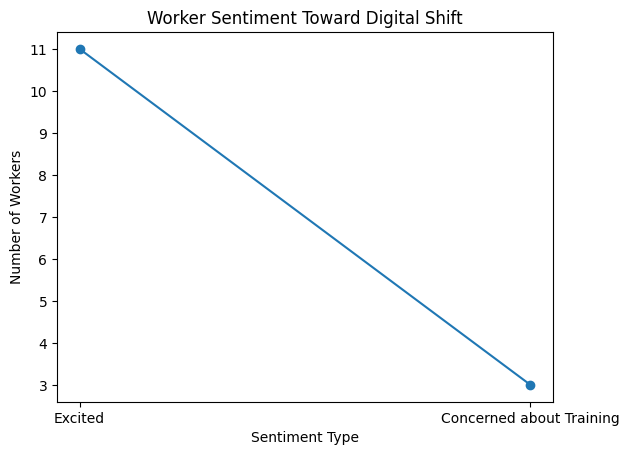

Overall Sentiment: Positive toward digital shift (11/12 excited); concerns about training (3 mentions).

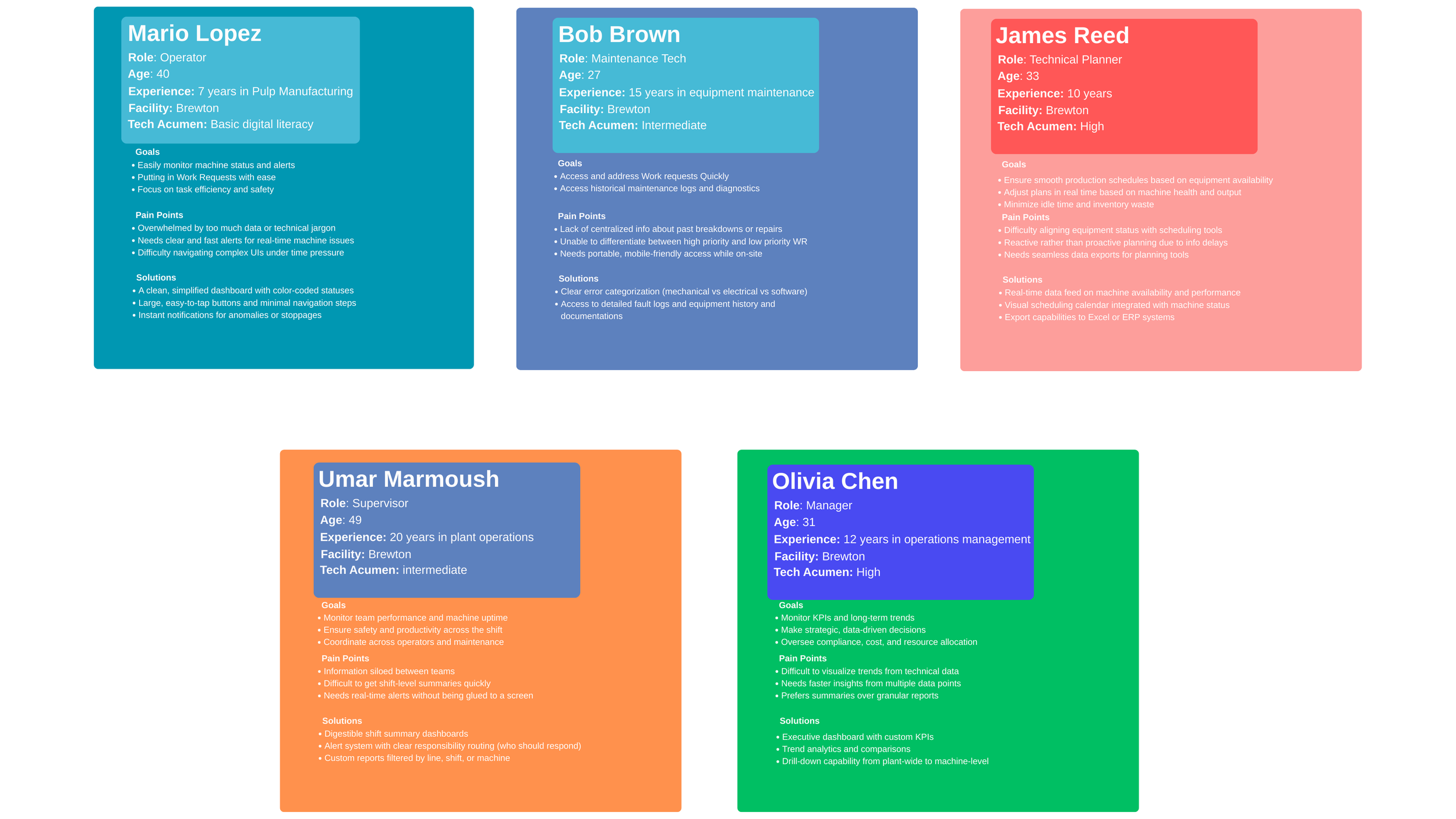

Persona Development

Based on the research, I created five personas representing the spectrum of factory workers' technical proficiency and interaction styles.

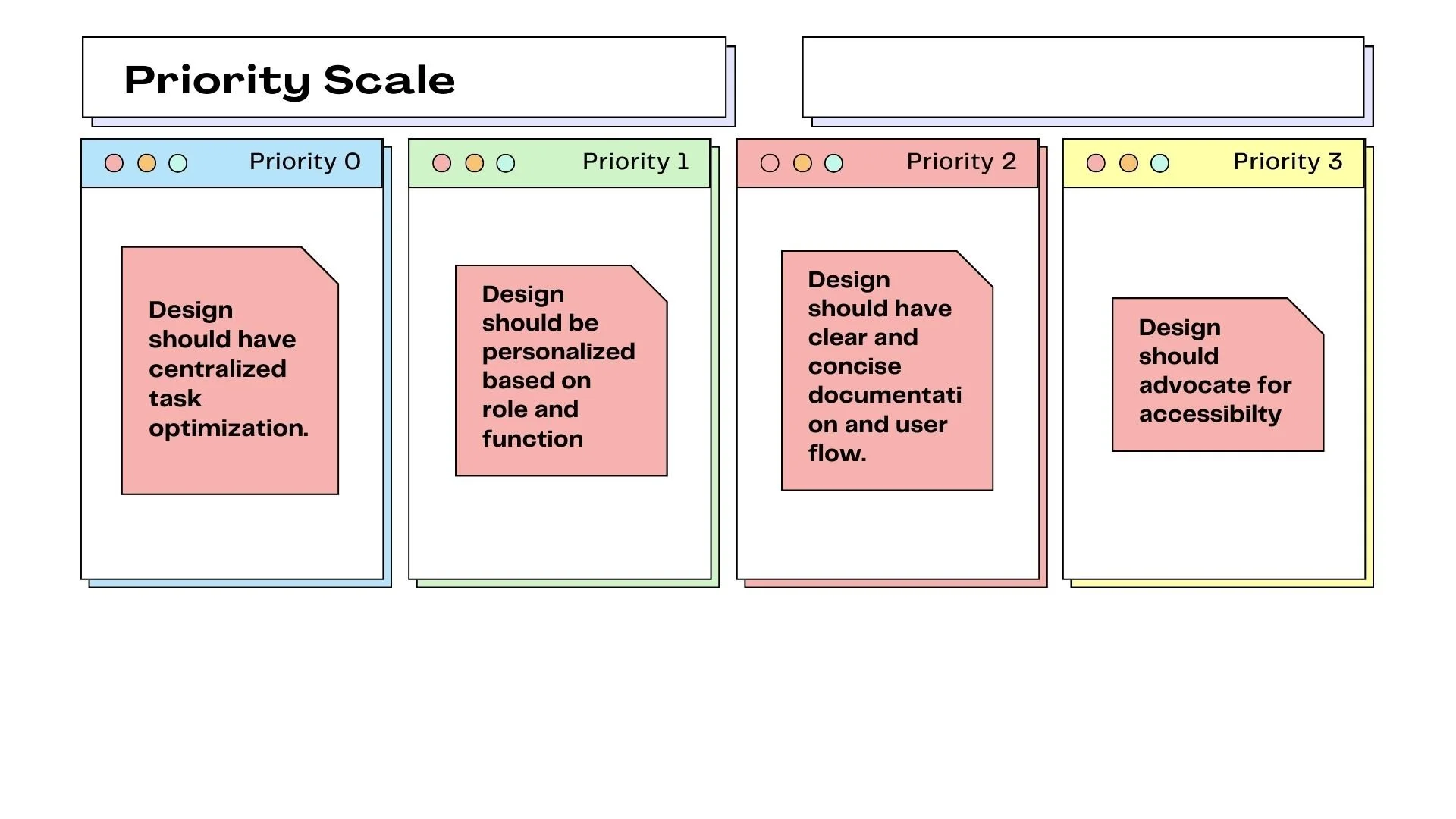

Design & Ideation

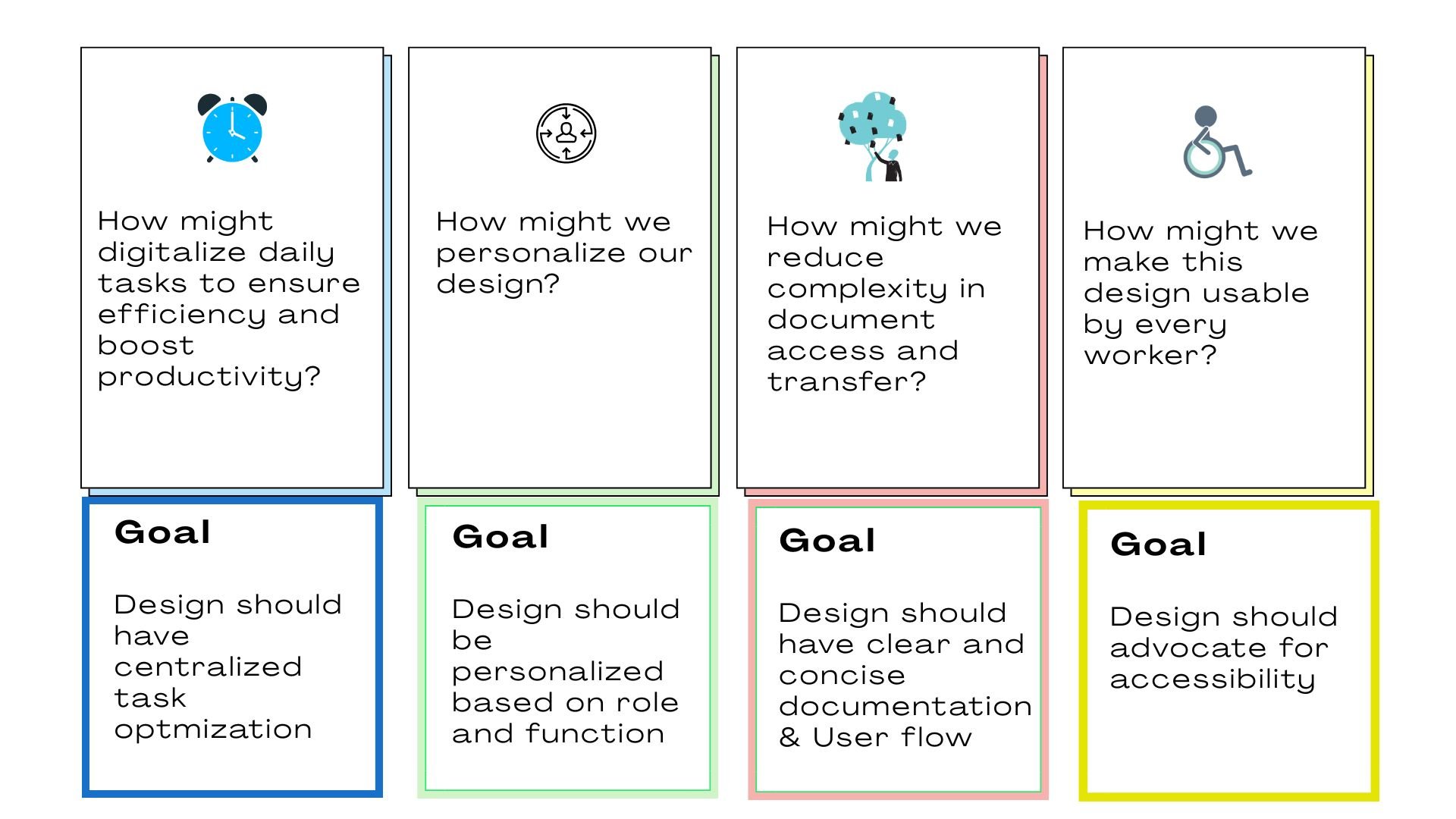

HMWs

Approved by Cross-functional Team

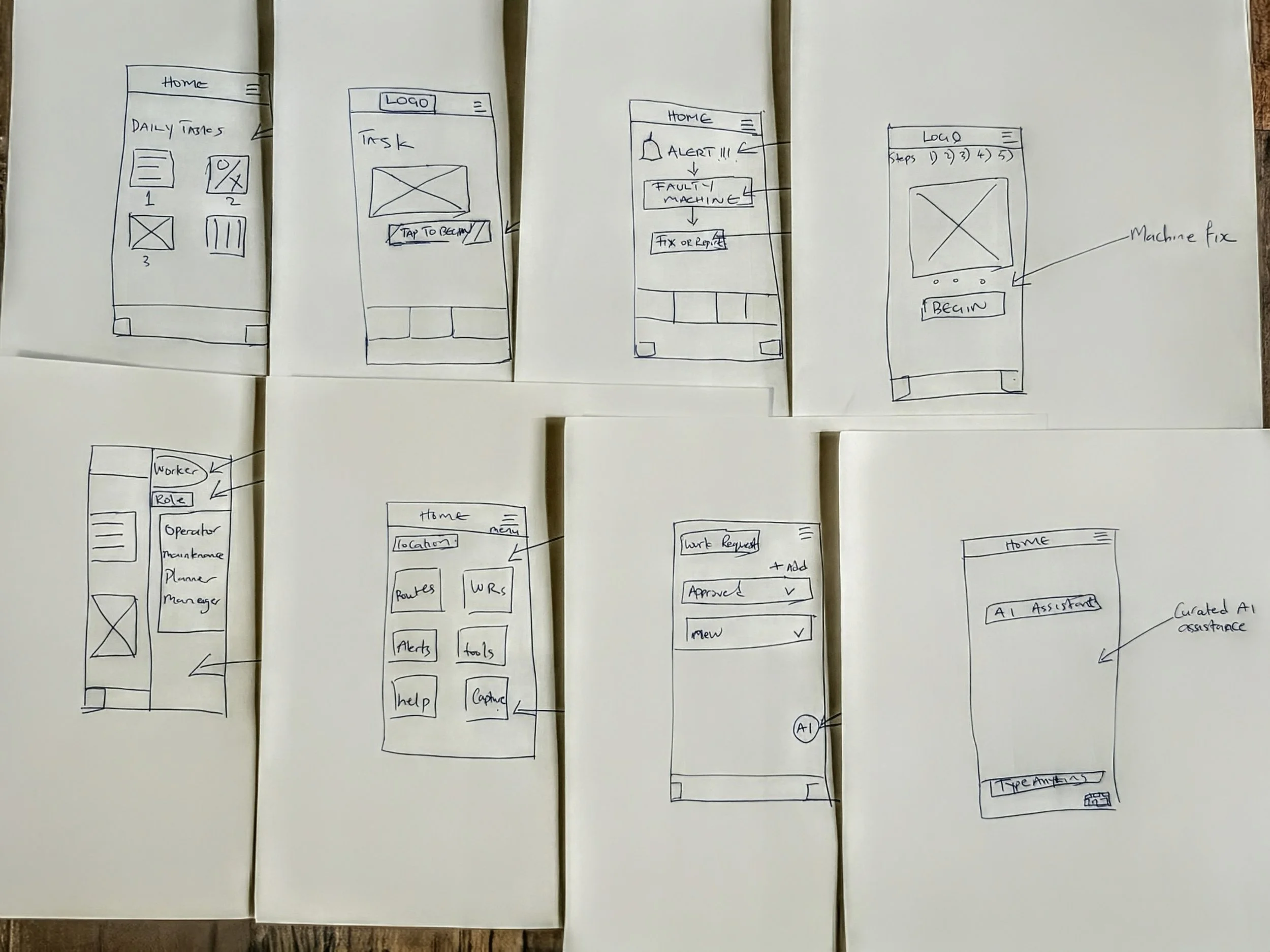

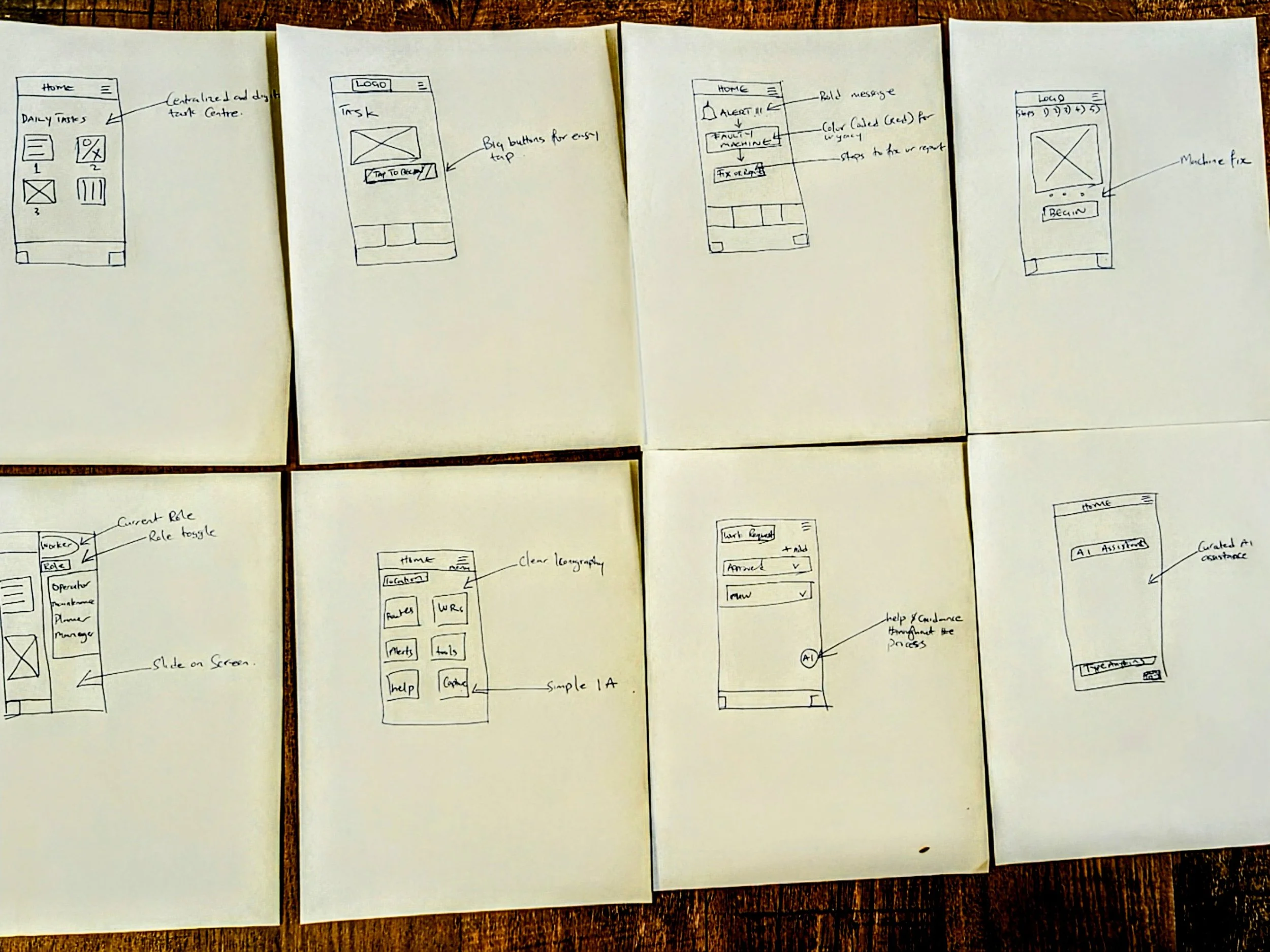

Crazy 8s Exercise

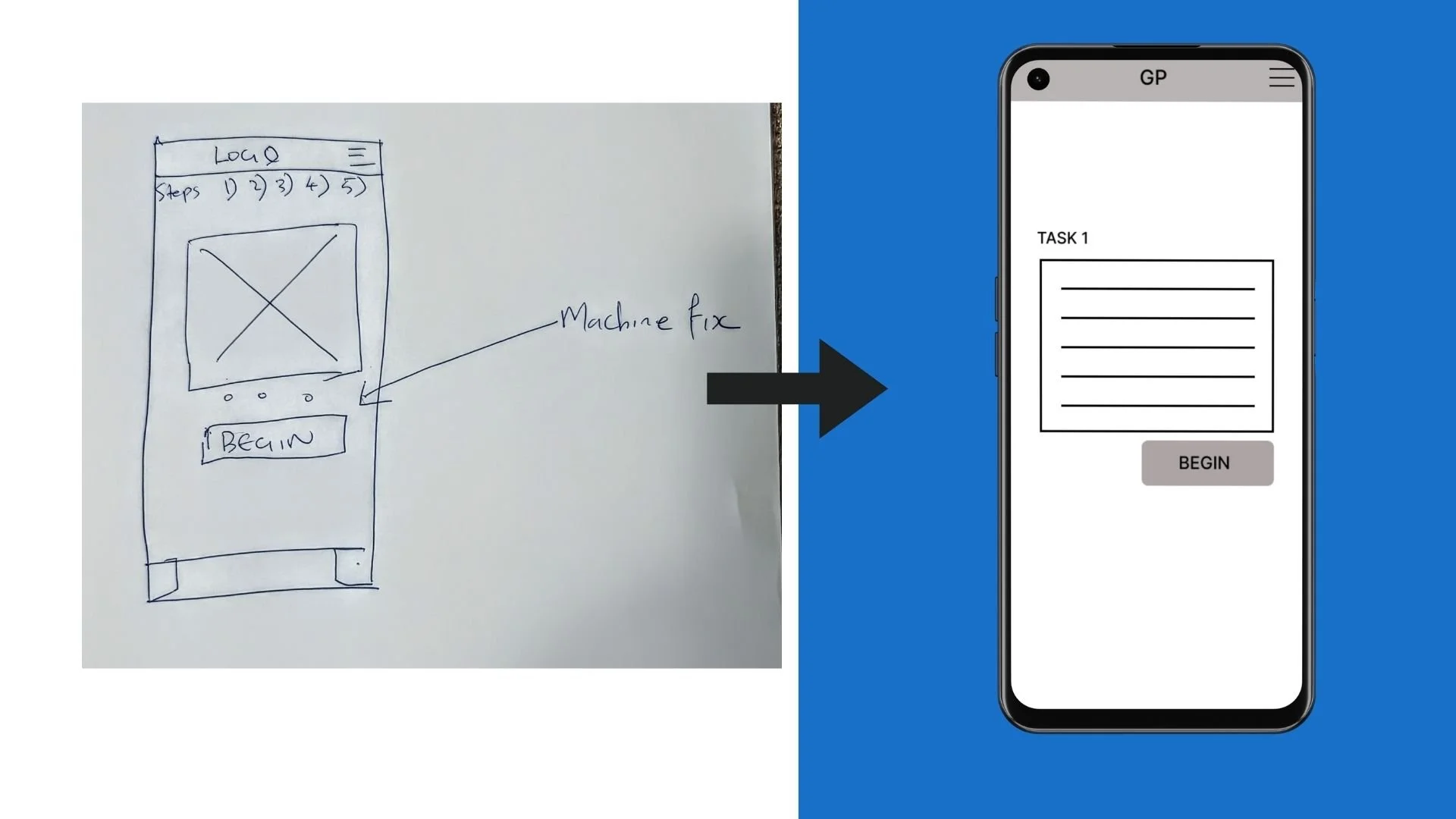

I conducted a Crazy 8s exercise to get an early feel for addressing the users’ needs. These sketches drew direct inspiration from the user interview pain points; Centralization, Personalization and simplicity.

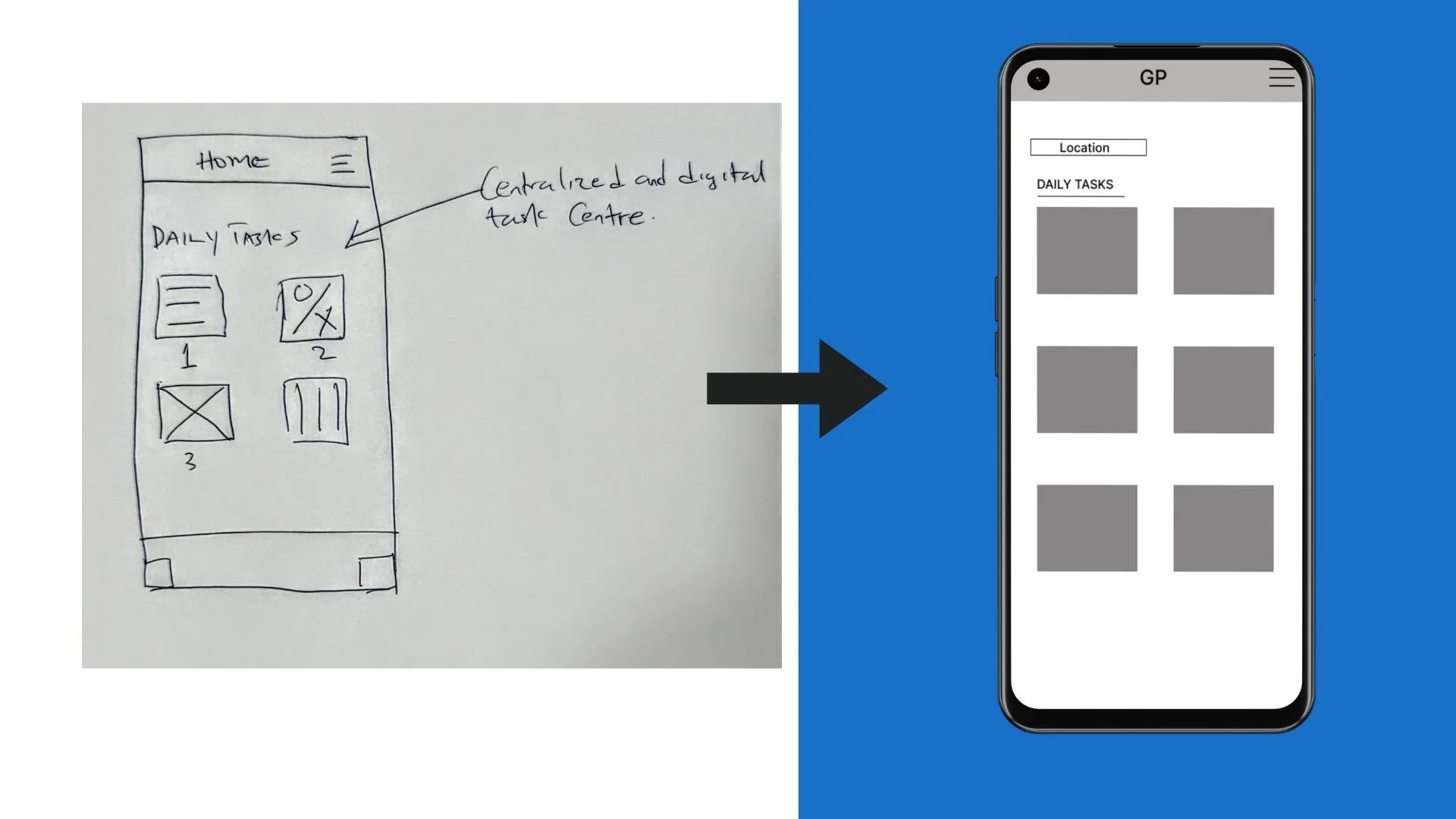

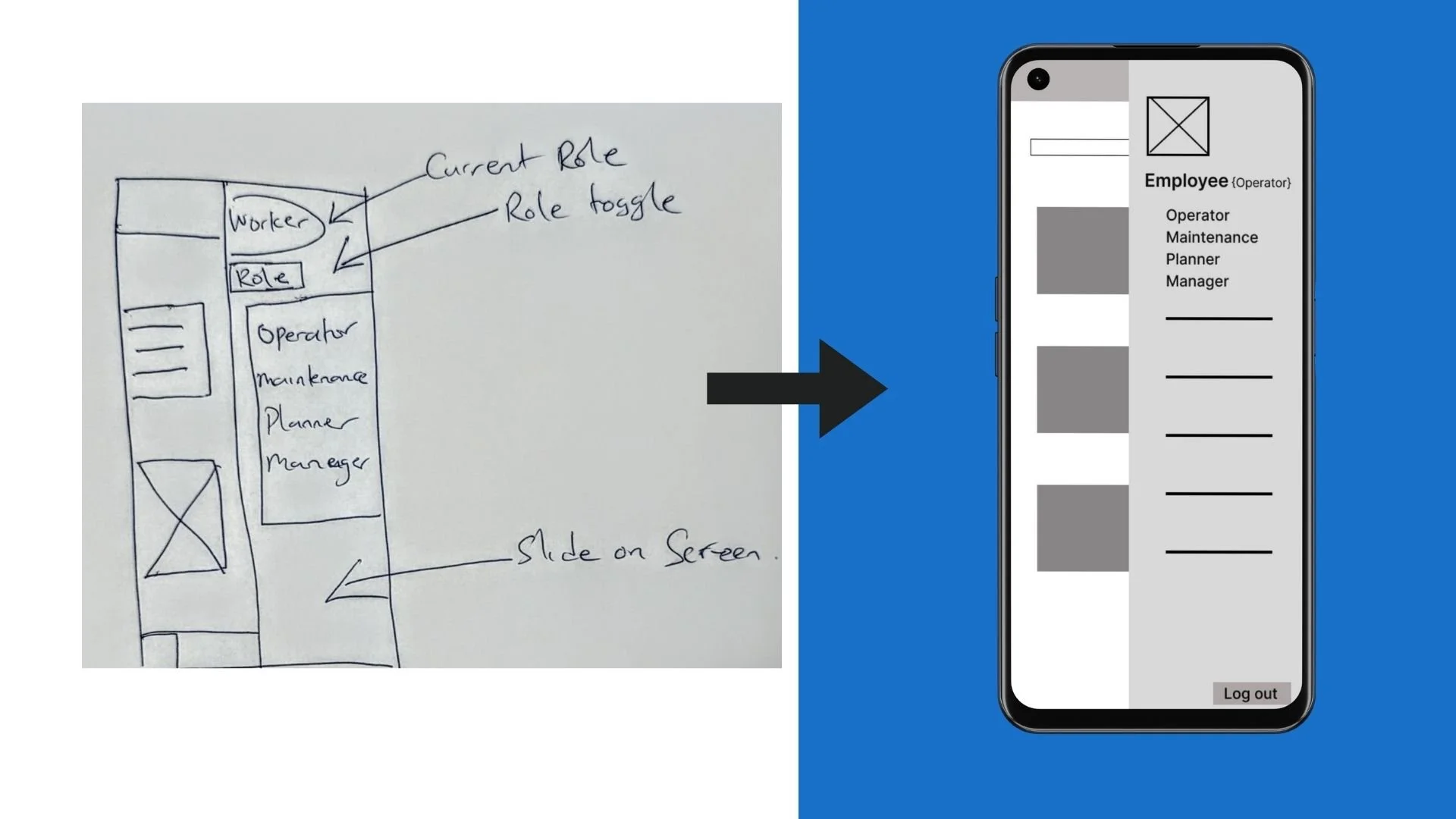

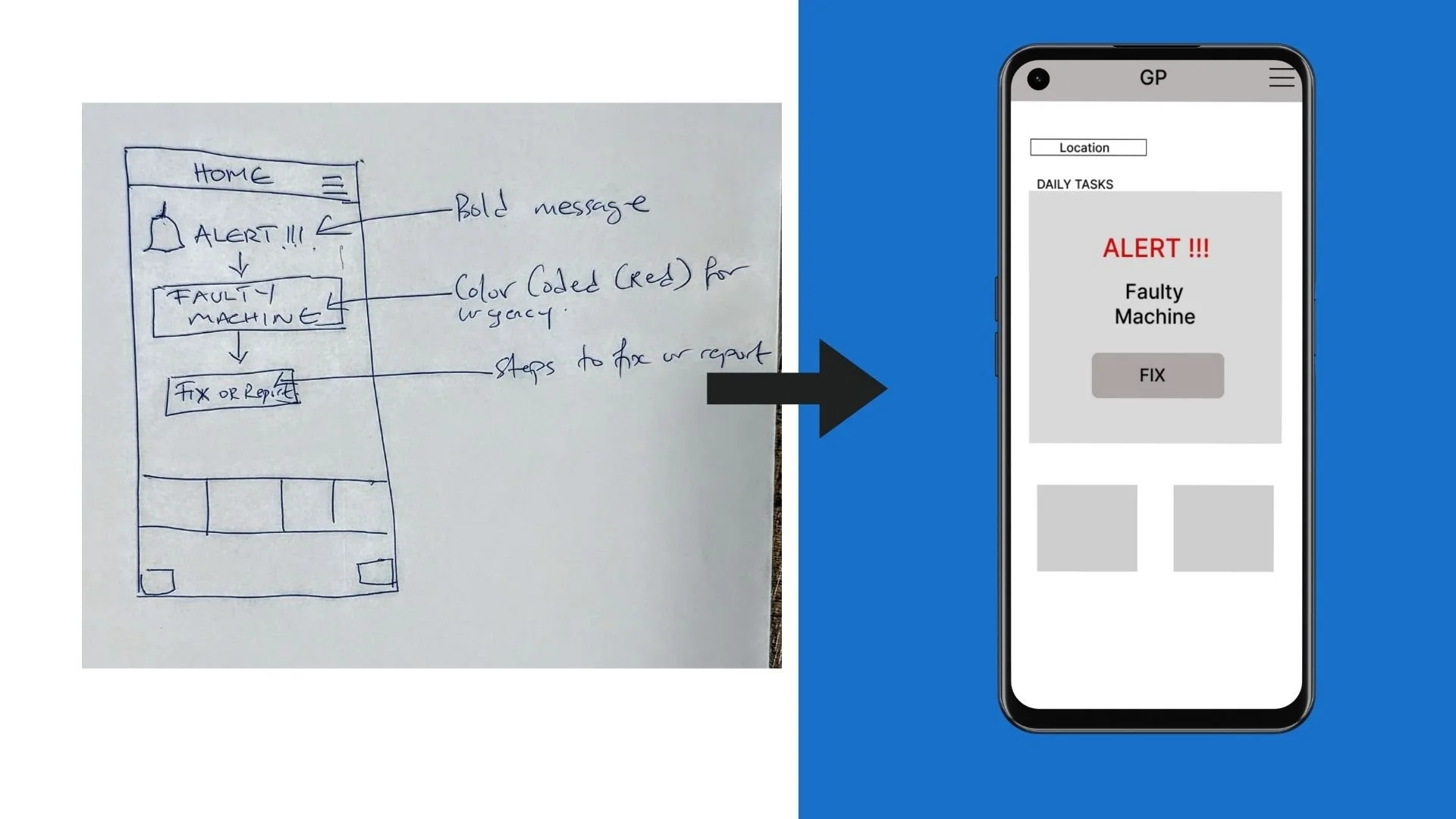

From Paper to Digital

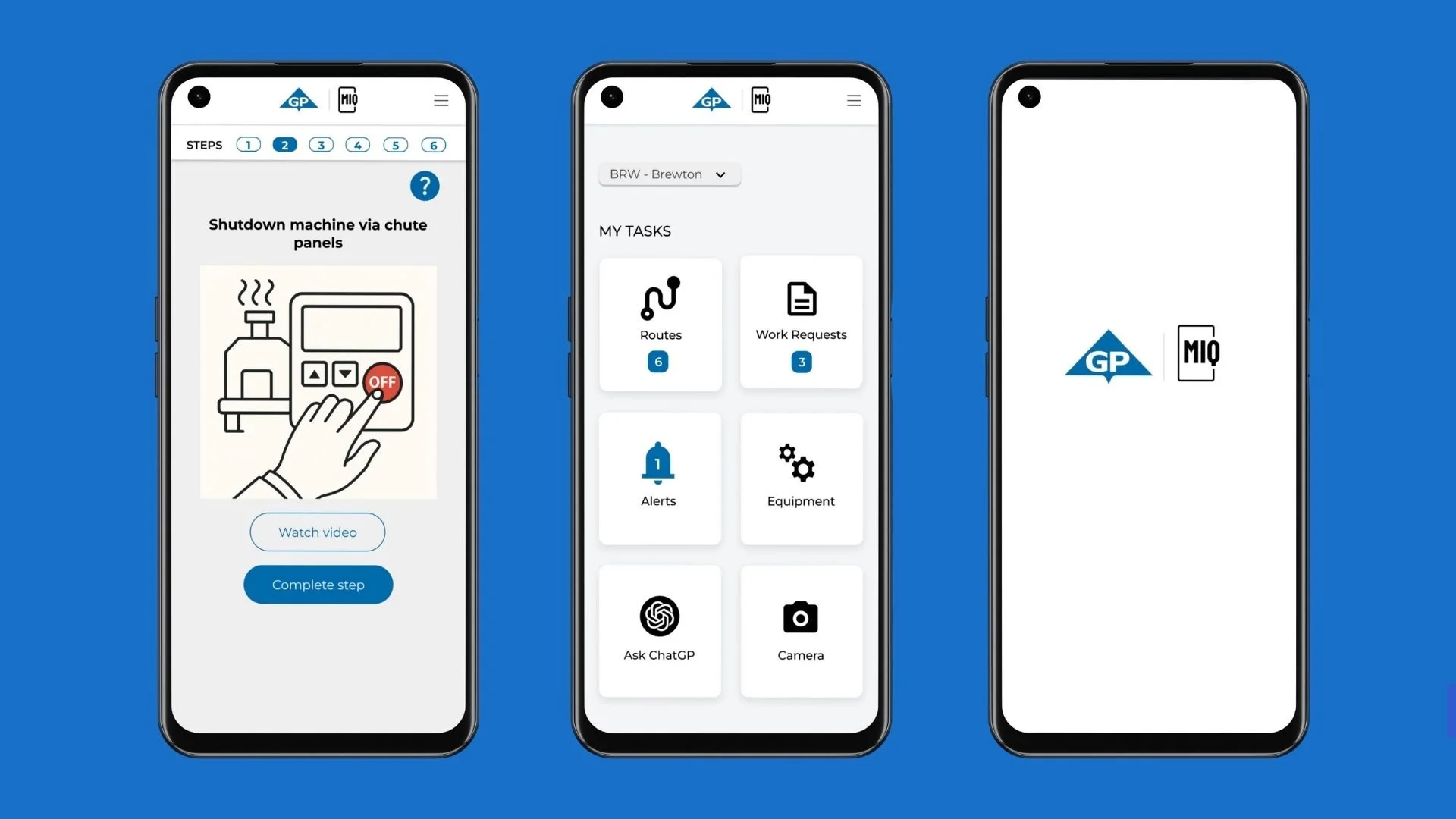

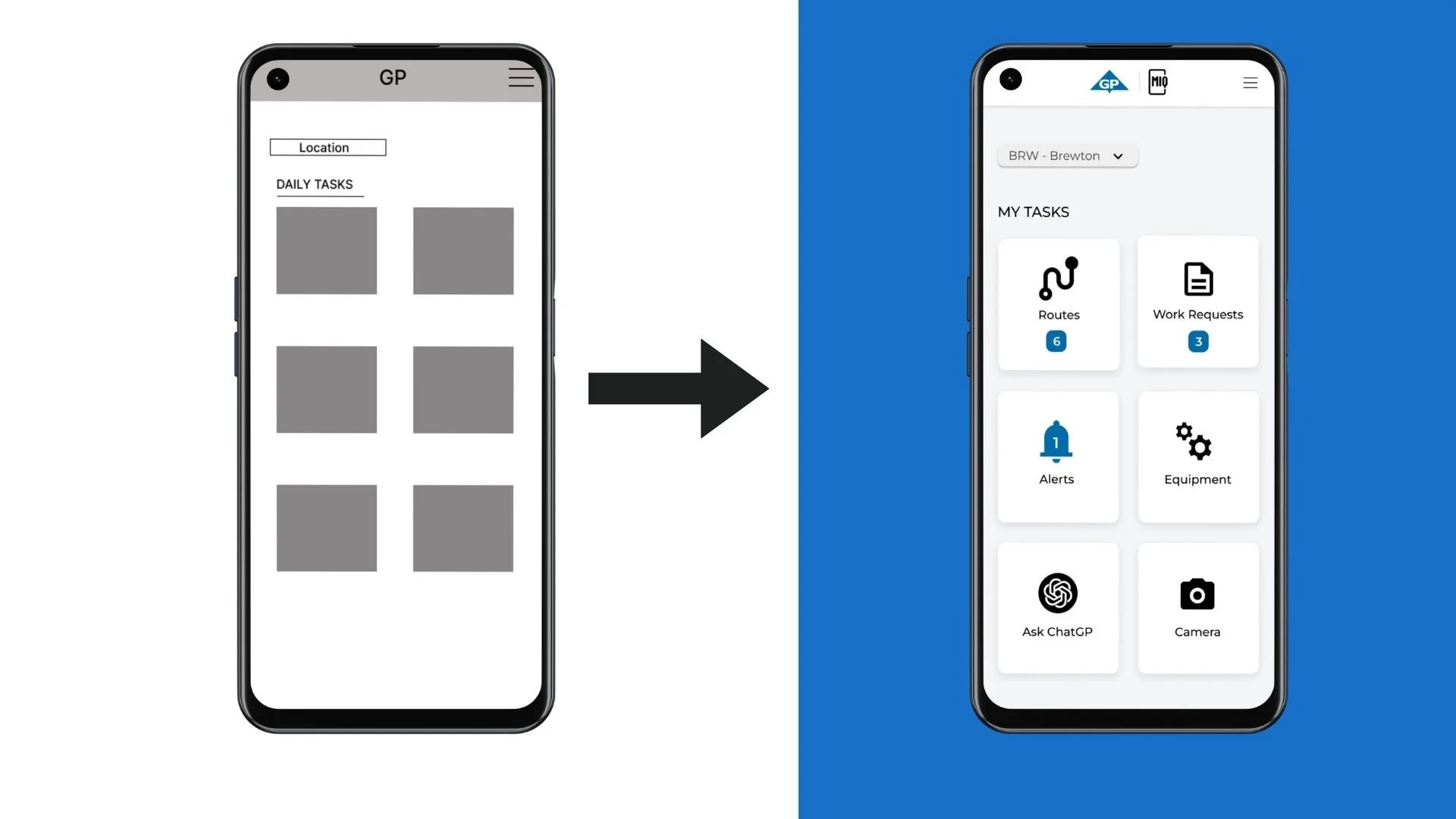

After sketching the wireframes by hand, it was now time to go into Figma to begin designing the low-fidelity prototypes. Keeping the Goal Statements in mind was the highest priority during this process.

Usability Testing

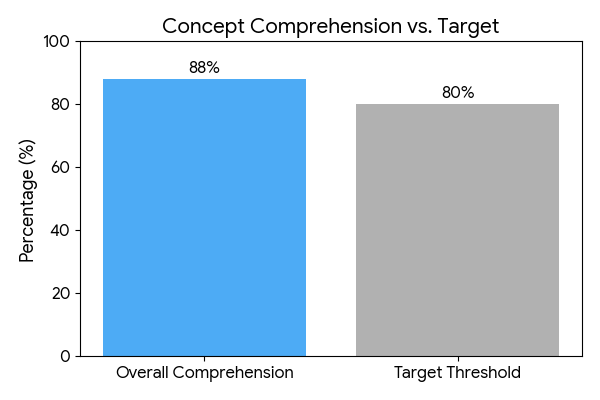

The primary goal of this study was to validate the conceptual framework of the MIQ mobile interface using low-fidelity prototypes. We aimed to identify friction points in task flows and data visualization before moving into high-fidelity production.

Feedback & Analysis

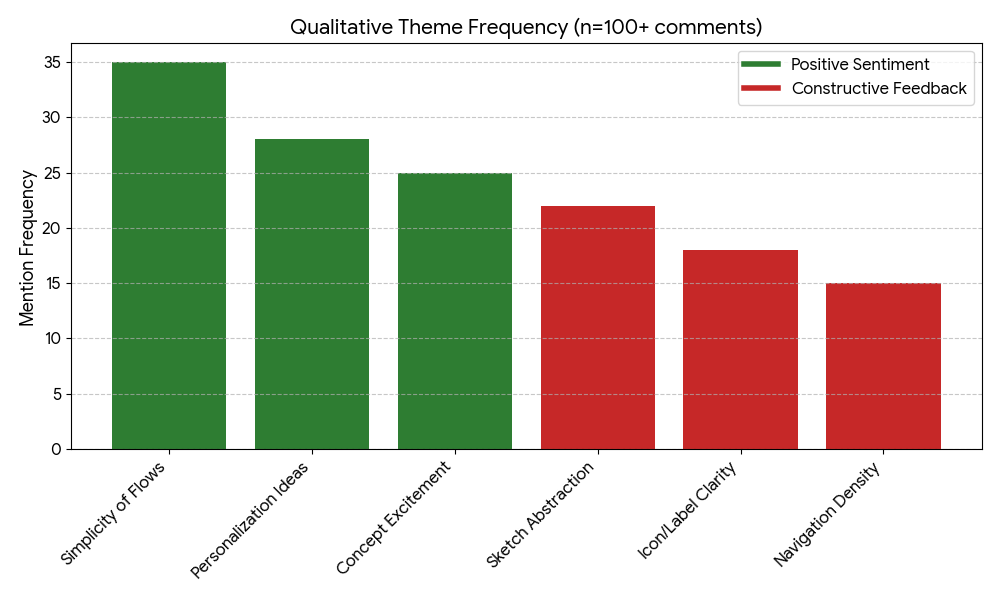

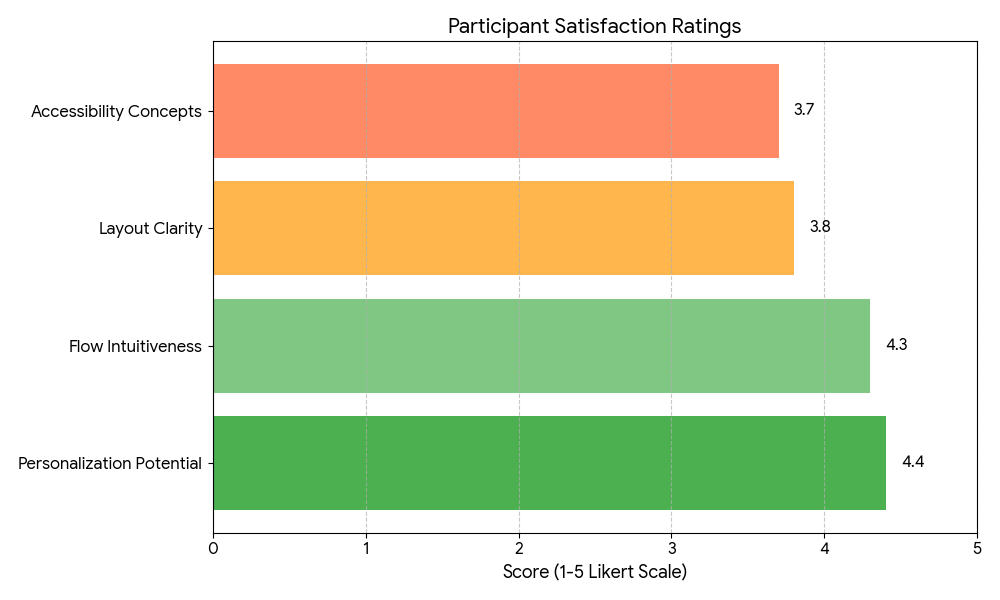

After receiving the raw data from the unmoderated Usability testing, I analyzed the participants' feedback, paying close attention to their honest criticisms and recommendations to improve and streamline MIQ.

Feedback Synthesis

Strengths: Participants appreciated the conceptual shift from paper to digital, with strong approval for centralized task dashboards and role-based personalization. Basic wireframes effectively conveyed efficiency gains.

Pain Points:

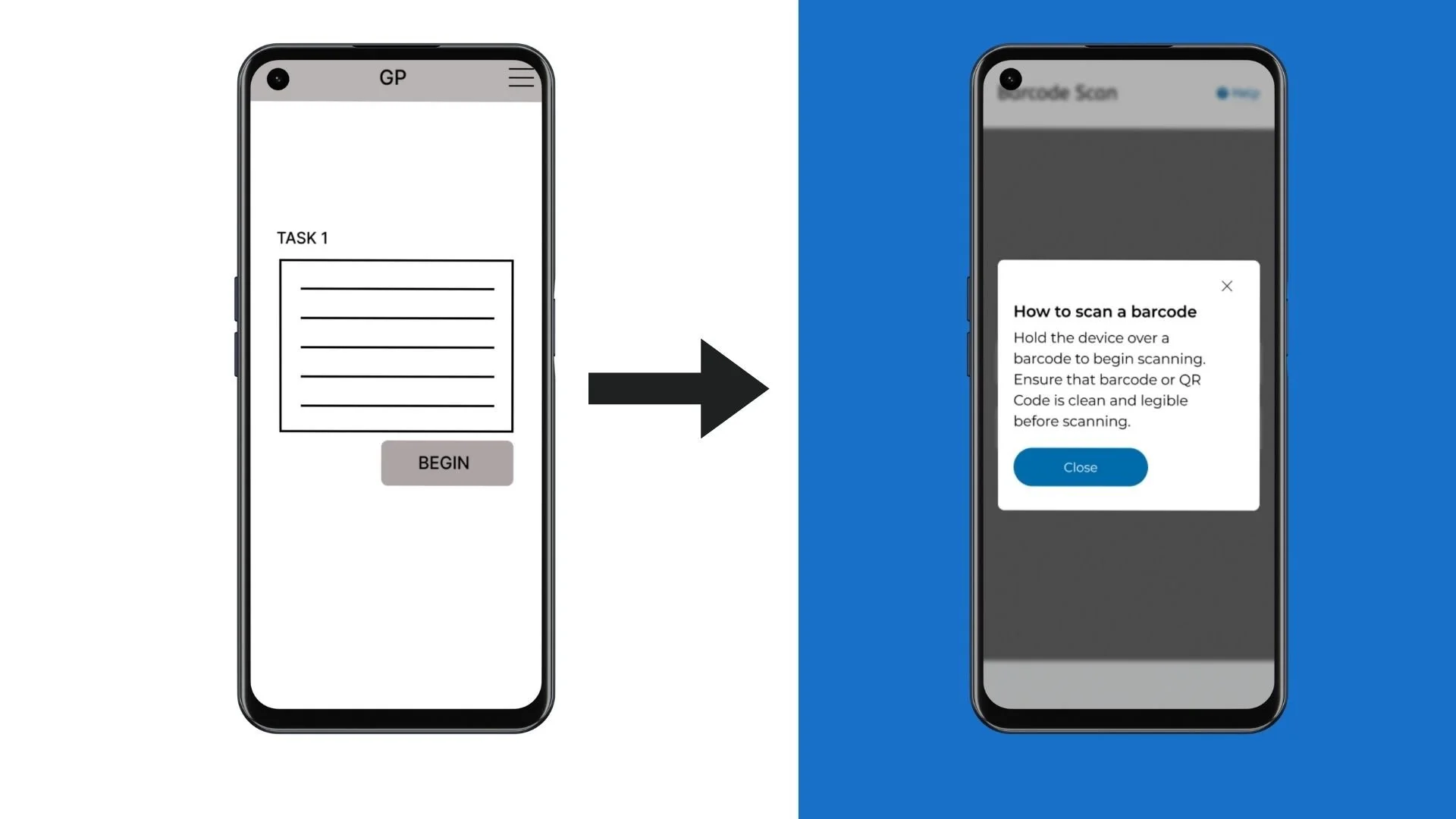

Abstract Representation: Low-fi sketches were hard for low-tech users to visualize (e.g., data charts as "lines" lacked context).

Icon and Labeling: Vague placeholders led to confusion; there is a need for intuitive symbols and text.

Accessibility: Early concepts like high-contrast were promising but needed more explicit features (e.g., voice sketches).

Flow Gaps: Linear designs missed back navigation; personalization lacked depth in sketches.

Iterations

From Low to High fidelity

I started to develop the high fidelity prototype, Using insights drawn from participant feedback in the Usability Study

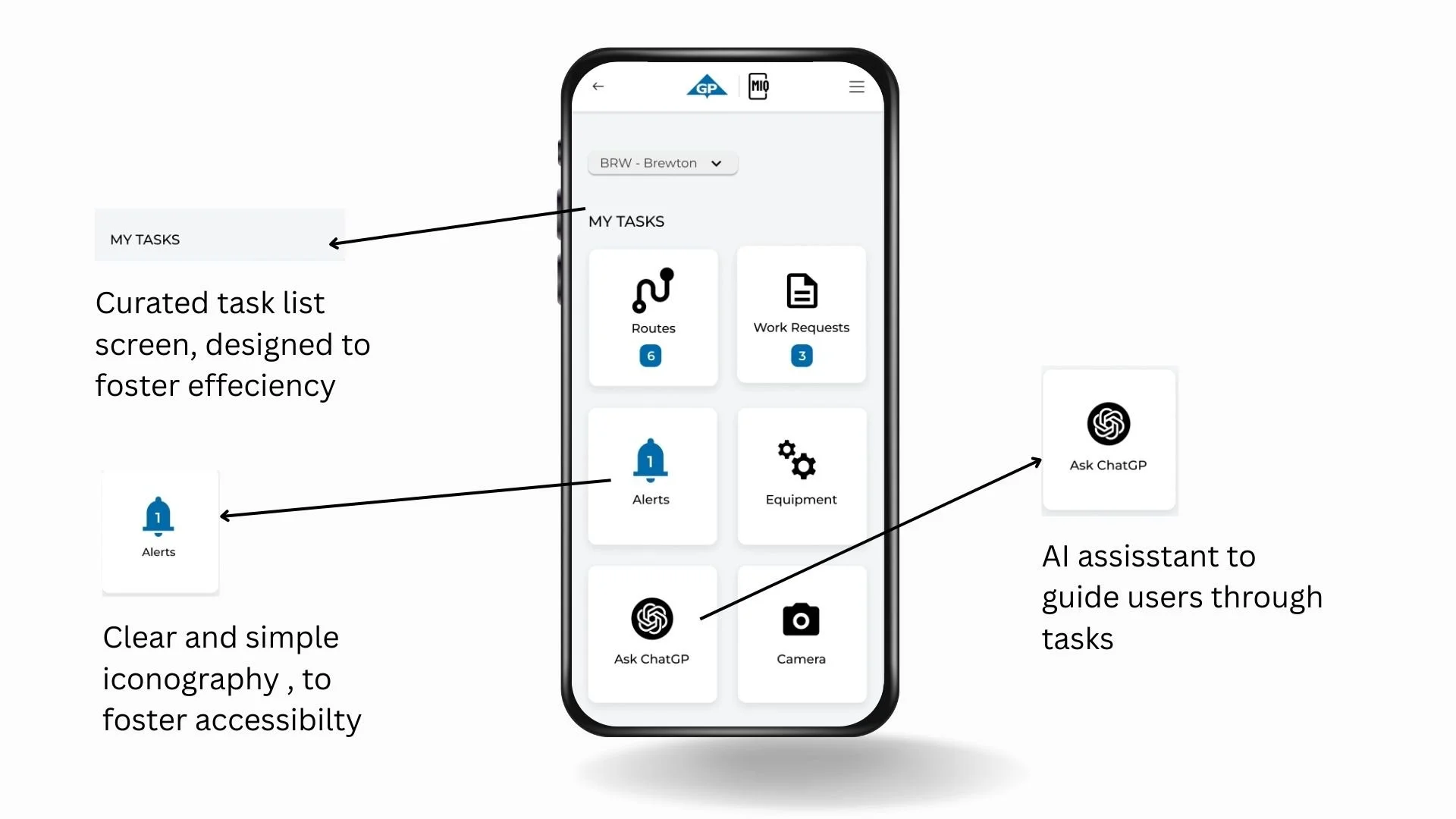

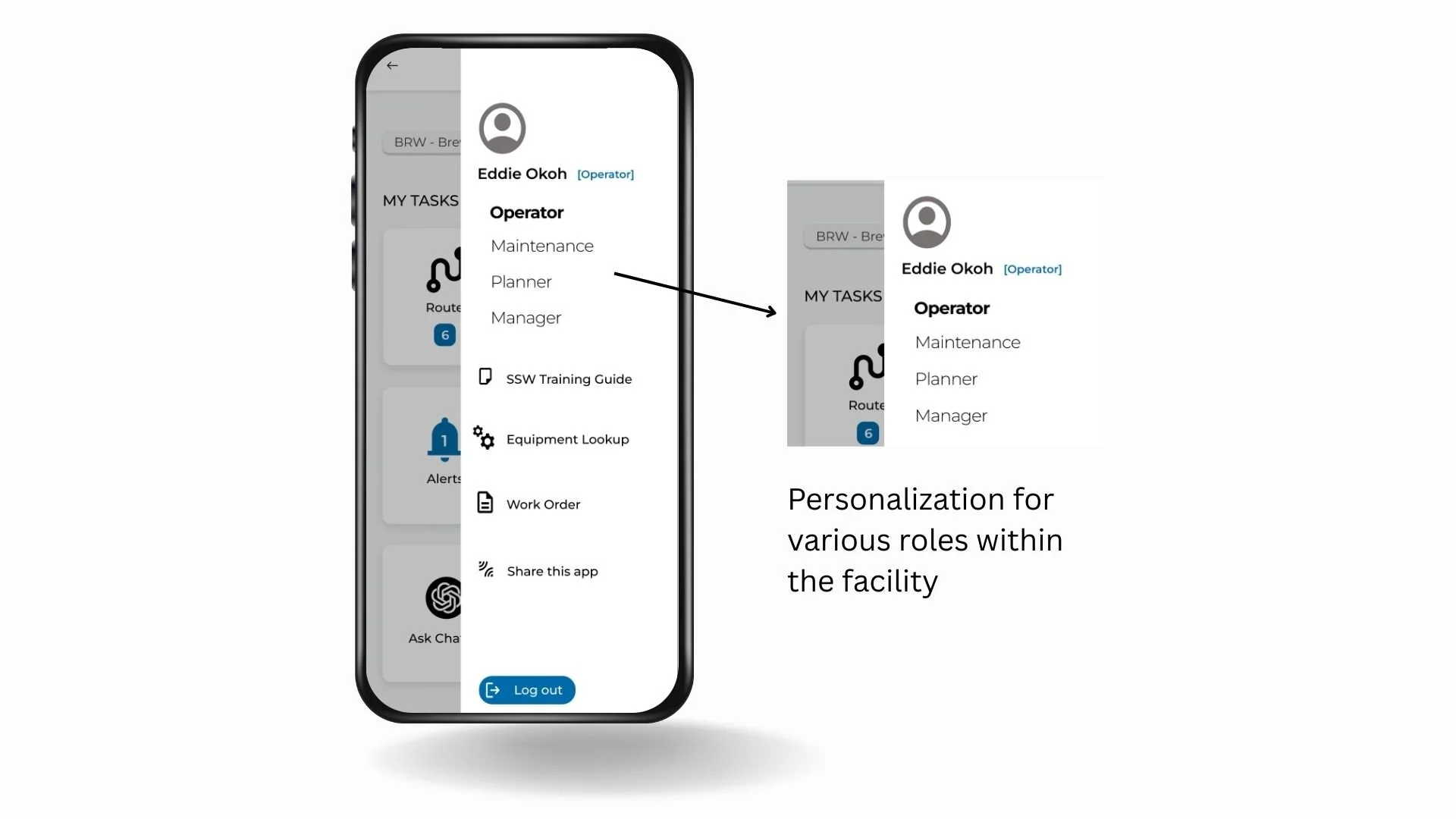

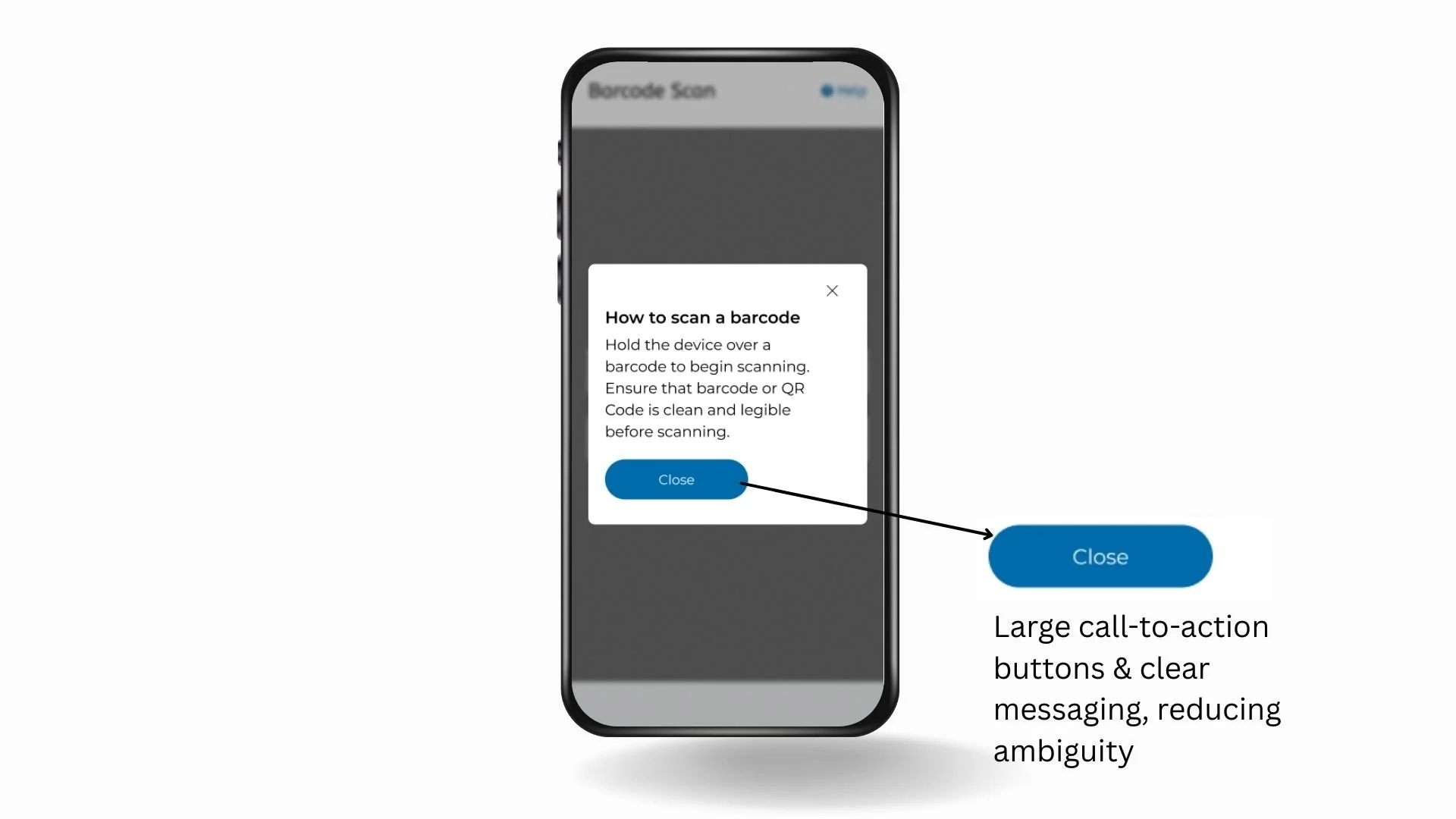

Dissecting the Essentials

Going back to the problem and goal statement, it was important to show how we have incorporated the users most important requests into how mock ups.

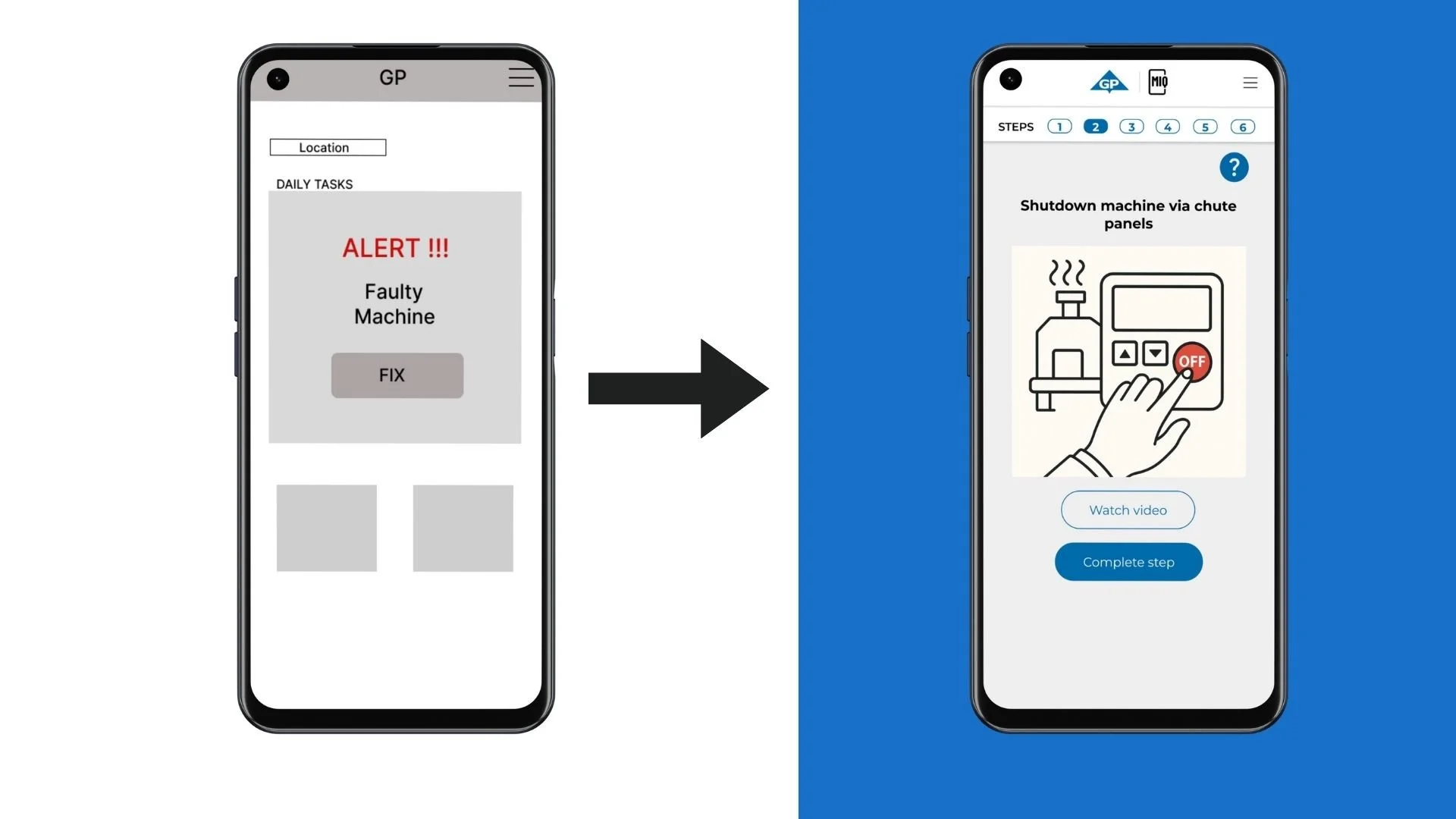

Task Completion

The Footage below simulates a facility operator troubleshooting a machine following step by step guidance from MIQ

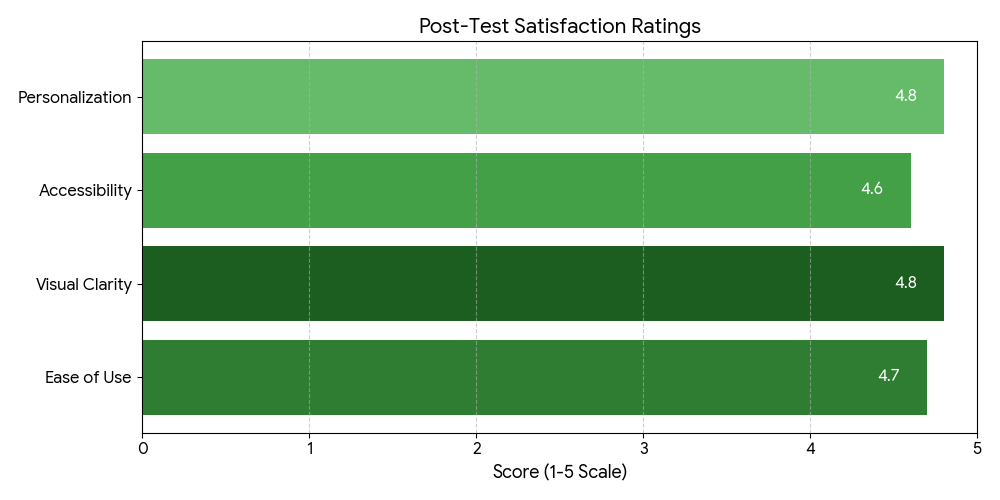

Usability Testing 2.0 Analysis

I returned the product to the potential users to test the high-fidelity prototype. The same methodology (Unmoderated testing) and test tasks were employed.

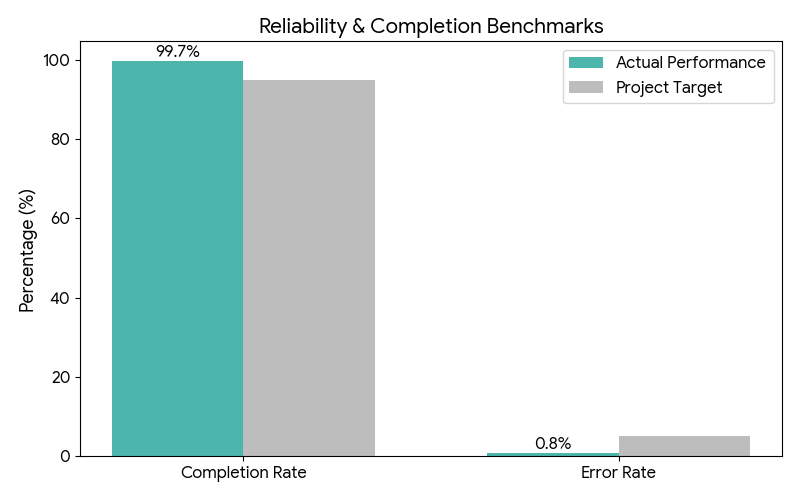

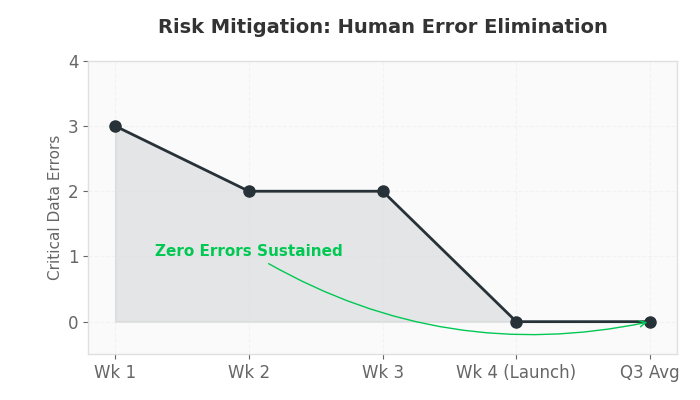

Performance Efficiency

The high-fidelity mobile ecosystem achieved nearly perfect task completion. By streamlining navigation, we realized a significant reduction in operational friction.

Completion Rate: 99.7% (Virtually eliminated drop-offs).

Time on Task: 3.6 minutes (35% faster than previous analog benchmark).

Error Rate: 0.8% (Negligible errors, mostly related to hardware connectivity rather than UI).

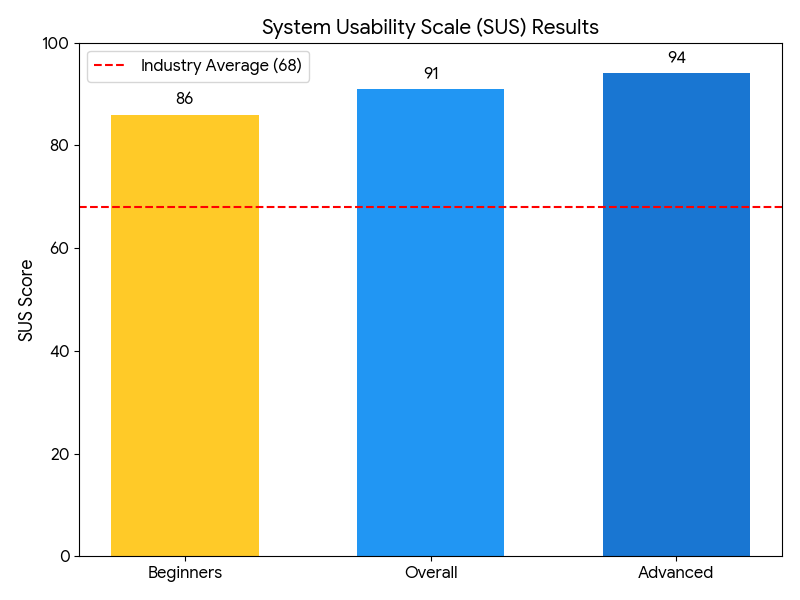

System Usability Scale (SUS)

The SUS is a standard industry metric for usability. A score above 68 is considered average; our result of 91 puts this system in the "Best Imaginable" category. Even our beginner persona cohort scored an 86, indicating the learning curve is exceptionally shallow.

Post Launch Impact

Post-launch, the MIQ ecosystem delivered immediate business value by slashing task completion times by 30% and boosting data accuracy by 25%. By grounding the UI in the rugged realities of the mill floor, the project achieved a 40% ROI in just one quarter, proving that user-centered design is a strategic profit driver, not just an aesthetic choice. Below are the visuals to support the data:

Voices of the Users

It was a thing of pride to here from the plant workers at Brewton about their experience with MIQ

Lesson learned

Empathy-Driven Design: This project reinforced the importance of empathy in creating informed designs. By visiting the plant and engaging directly with workers, I gained a deeper understanding of their pain points, enabling targeted solutions to their operational challenges.

Effective Communication and Collaboration: Working closely with team members, including product managers and engineers, enhanced my analytical skills and provided a clearer view of the project's broader impact on productivity and ROI.

The Critical Role of Feedback: Feedback is essential for success; without it, a project is doomed from the start. Witnessing the iterative improvements based on user input filled me with pride as a designer, validating the user-centered approach.